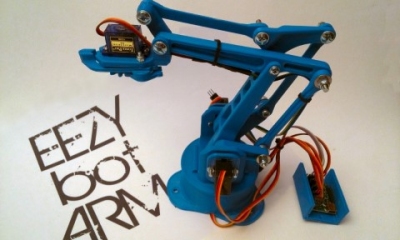

EEZYbotARM

Kaivuri testi neljällä moottorilla

#include <Servo.h> //Servo library

Servo servo_1; //initialize a servo object for the connected servo

Servo servo_2; //initialize a servo object for the connected servo

Servo servo_3; //initialize a servo object for the connected servo

Servo servo_4; //initialize a servo object for the connected servo

int angle1 = 0;

int angle2 = 0;

int angle3 = 0;

int angle4 = 0;

int potentio1 = A1; // initialize the A0analog pin for potentiometer

int potentio2 = A0; // initialize the A1analog pin for potentiometer

int potentio3 = A2; // initialize the A1analog pin for potentiometer

int potentio4 = A3; // initialize the A1analog pin for potentiometer

#define SERVO1PIN 7

#define SERVO2PIN 9

#define SERVO3PIN 10

#define SERVO4PIN 6

void setup()

{

servo_1.attach(SERVO1PIN); // attach the signal pin of servo to pin9 of arduino

servo_2.attach(SERVO2PIN); // attach the signal pin of servo to pin9 of arduino

servo_3.attach(SERVO3PIN); // attach the signal pin of servo to pin9 of arduino

servo_4.attach(SERVO4PIN); // attach the signal pin of servo to pin9 of arduino

}

void loop()

{

angle1 = analogRead(potentio1); // reading the potentiometer value between 0 and 1023

angle1 = map(angle1, 0, 1023, 60, 140); // scaling the potentiometer value to angle value for servo between 0 and 180)

servo_1.write(angle1); //command to rotate the servo to the specified angle

delay(5);

angle2 = analogRead(potentio2); // reading the potentiometer value between 0 and 1023

angle2 = map(angle2, 0, 1023, 0, 179); // scaling the potentiometer value to angle value for servo between 0 and 180)

servo_2.write(angle2); //command to rotate the servo to the specified angle

delay(5);

angle3 = analogRead(potentio3); // reading the potentiometer value between 0 and 1023

angle3 = map(angle3, 0, 1023, 30, 160); // scaling the potentiometer value to angle value for servo between 0 and 180)

servo_3.write(angle3); //command to rotate the servo to the specified angle

delay(5);

angle4 = analogRead(potentio4); // reading the potentiometer value between 0 and 1023

angle4 = map(angle4, 0, 1023, 30, 160); // scaling the potentiometer value to angle value for servo between 0 and 180)

servo_4.write(angle4); //command to rotate the servo to the specified angle

delay(5);

}

Oppiva robottikäsi

// Code written by Ryan Chan; it is pretty inefficient, but gets the job // done, I challenge you to make it more efficient!

//*IMPORTANT CHANGES IN VERSION 2: LEDs 4 and 5 have been moved to pins // 7 and 8 respectively; Buttons 1 and 2 have been moved to pins 12 and // 13 respectively. This is to make wiring easier.

#include <Servo.h>

Servo servo1; //Servos

Servo servo2;

Servo servo3;

const int LED1 = 2; //LEDs

const int LED2 = 3;

const int LED3 = 4;

const int LED4 = 7;

const int LED5 = 8;

const int button1 = 12; //Buttons

const int button2 = 13;

int button1Presses = 0; //Button values

boolean button2Pressed = false;

const int pot1 = A0; //Potentimeters

const int pot2 = A1;

const int pot3 = A2;

int pot1Val; //Potentimeter values

int pot2Val;

int pot3Val;

int pot1Angle;

int pot2Angle;

int pot3Angle;

int servo1PosSaves[] = {1,1,1,1,1}; //position saves

int servo2PosSaves[] = {1,1,1,1,1};

int servo3PosSaves[] = {1,1,1,1,1};

void setup() {

servo1.attach(7);

// Set up everything and will run once;

// attach servos and define the pin modes

servo2.attach(8);

servo3.attach(9);

pinMode(LED1, OUTPUT);

pinMode(LED2, OUTPUT);

pinMode(LED3, OUTPUT);

pinMode(LED4, OUTPUT);

pinMode(LED5, OUTPUT);

pinMode(button1, INPUT);

pinMode(button2, INPUT);

Serial.begin(9600);

}

void loop() {

// put your main code here, to run repeatedly:

pot1Val = analogRead(pot1);

// This will read the values from the potentimeters and store it...

pot1Angle = map(pot1Val, 0, 1023, 0, 179);

// ... and this will map the values from the potentiometers to

// values the servos can use and store it for later use

pot2Val = analogRead(pot2);

pot2Angle = map(pot2Val, 0, 1023, 0, 179);

pot3Val = analogRead(pot3);

pot3Angle = map(pot3Val, 0, 1023, 0, 179);

servo1.write(pot1Angle);

// These will make the servos move to the mapped angles

servo2.write(pot2Angle);

servo3.write(pot3Angle);

if(digitalRead(button1) == HIGH){

// This will check how many times button1 is pressed and save

// the positions to an array depending on how many times it is

// pressed; switch/case works like a if statement

button1Presses++;

switch(button1Presses){

case 1:

servo1PosSaves[0] = pot1Angle;

servo2PosSaves[0] = pot2Angle;

servo3PosSaves[0] = pot3Angle;

digitalWrite(LED1, HIGH);

Serial.println("Pos 1 Saved");

break;

case 2:

servo1PosSaves[1] = pot1Angle;

servo2PosSaves[1] = pot2Angle;

servo3PosSaves[1] = pot3Angle;

digitalWrite(LED2, HIGH);

Serial.println("Pos 2 Saved");

break;

case 3:

servo1PosSaves[2] = pot1Angle;

servo2PosSaves[2] = pot2Angle;

servo3PosSaves[2] = pot3Angle;

digitalWrite(LED3, HIGH);

Serial.println("Pos 3 Saved");

break;

case 4:

servo1PosSaves[3] = pot1Angle;

servo2PosSaves[3] = pot2Angle;

servo3PosSaves[3] = pot3Angle;

digitalWrite(LED4, HIGH);

Serial.println("Pos 4 Saved");

break;

case 5:

servo1PosSaves[4] = pot1Angle;

servo2PosSaves[4] = pot2Angle;

servo3PosSaves[4] = pot3Angle;

digitalWrite(LED5, HIGH);

Serial.println("Pos 5 Saved");

break;

}

}

if(digitalRead(button2) == HIGH){

// Pretty self-explnatory here

button2Pressed = true;

}

if(button2Pressed){

// if the boolean button2Press is true, then the servos

// will run though all their saved positionsfor(int i = 0; i < 5; i++){

servo1.write(servo1PosSaves[i]);

servo2.write(servo2PosSaves[i]);

servo3.write(servo3PosSaves[i]);

Serial.println(" potentimeter Angles: ");

Serial.println(servo1PosSaves[i]);

Serial.println(servo2PosSaves[i]);

Serial.println(servo3PosSaves[i]);

delay(1050);

}

}

delay(300);

}

Joystick Sensor Serial Read

TNG Robotics | www.tngrobotics.ca

Title | Joystick Sensor Serial Read

Connect | Servo to Arduino digital pin 5

Published | October 29, 2016

*/

const int VRx = 0; // Connect to Analog Pin 0

const int VRy = 1; // Connect to Analog Pin 1

const int SW = 4; // Connect to Digital Pin 4

void setup() {

pinMode(SW, INPUT);

digitalWrite(SW, HIGH);

Serial.begin(9600);

}

void loop() {

Serial.print("x-axis tilt: ");

Serial.println(analogRead(VRx));

Serial.print("y-axis tilt: ");

Serial.println(analogRead(VRy));

Serial.print("switch: ");

Serial.println(digitalRead(SW));

delay(800);

}

Testing the DC Motors 2

/**

* Bruno Santos, 2013

* feiticeir0@whatgeek.com.pt

* Small code to test DC motors - 2x with a L298 Dual H-Bridge Motor Driver

* Free to share

**/

//Testing the DC Motors

//Define Pins

//Motor A

int enableA = 10;

int pinA1 = 2;

int pinA2 = 3;

//Motor B

int enableB = 9;

int pinB1 = 4;

int pinB2 = 5;

//define time for run

// in milliseconds

int running = 10000; //10 secons

boolean play;

void setup() {

Serial.begin (9600);

//configure pin modes

pinMode (enableA, OUTPUT);

pinMode (pinA1, OUTPUT);

pinMode (pinA2, OUTPUT);

pinMode (enableB, OUTPUT);

pinMode (pinB1, OUTPUT);

pinMode (pinB2, OUTPUT);

play = true;

}

//motor functions

void motorAforward() {

digitalWrite (pinA1, HIGH);

digitalWrite (pinA2, LOW);

}

void motorBforward() {

digitalWrite (pinB1, LOW);

digitalWrite (pinB2, HIGH);

}

void motorAbackward() {

digitalWrite (pinA1, LOW);

digitalWrite (pinA2, HIGH);

}

void motorBbackward() {

digitalWrite (pinB1, HIGH);

digitalWrite (pinB2, LOW);

}

void motorAstop() {

digitalWrite (pinA1, HIGH);

digitalWrite (pinA2, HIGH);

}

void motorBstop() {

digitalWrite (pinB1, HIGH);

digitalWrite (pinB2, HIGH);

}

void motorAcoast() {

digitalWrite (pinA1, LOW);

digitalWrite (pinA2, LOW);

}

void motorBcoast() {

digitalWrite (pinB1, LOW);

digitalWrite (pinB2, LOW);

}

void motorAon() {

digitalWrite (enableA, HIGH);

}

void motorBon() {

digitalWrite (enableB, HIGH);

}

void motorAoff() {

digitalWrite (enableA, LOW);

}

void motorBoff() {

digitalWrite (enableB, LOW);

}

// Movement functions

void forward (int duration) {

motorAforward();

motorBforward();

delay (duration);

}

void backward (int duration) {

motorAbackward();

motorBbackward();

delay (duration);

}

void left (int duration) {

motorAbackward();

motorBforward();

delay (duration);

}

void right (int duration) {

motorAforward();

motorBbackward();

delay (duration);

}

void coast (int duration) {

motorAcoast();

motorBcoast();

delay (duration);

}

void breakRobot (int duration) {

motorAstop();

motorBstop();

delay (duration);

}

void disableMotors() {

motorAoff();

motorBoff();

}

void enableMotors() {

motorAon();

motorBon();

}

void loop() {

enableMotors();

while (play) {

//Forward for 1,5s

Serial.println ("forward...");

forward (1500);

//turn right

Serial.println ("right...");

right (500);

//Forward for 1,5s

Serial.println ("forward...");

forward (1500);

//turn left

Serial.println ("left...");

left (1000);

//Forward for 1,5s

Serial.println ("forward...");

forward (1500);

if (millis() > running) {

play = false;

Serial.println ("Falsing");

}

};

//disable motors

disableMotors();

}

Testing the DC Motors

* Bruno Santos, 2013

* feiticeir0@whatgeek.com.pt

* Small code to test DC motors - 2x with a L298 Dual H-Bridge Motor Driver

* Free to share

**/

//Testing the DC Motors

//Define Pins

//Motor A

int enableA = 10;

int pinA1 = 2;

int pinA2 = 3;

//Motor B

int enableB = 9;

int pinB1 = 4;

int pinB2 = 5;

void setup() {

Serial.begin (9600);

//configure pin modes

pinMode (enableA, OUTPUT);

pinMode (pinA1, OUTPUT);

pinMode (pinA2, OUTPUT);

pinMode (enableB, OUTPUT);

pinMode (pinB1, OUTPUT);

pinMode (pinB2, OUTPUT);

}

void loop() {

//enabling motor A

Serial.println ("Enabling Motor A");

digitalWrite (enableA, HIGH);

//do something

//forward

Serial.println ("Forward");

digitalWrite (pinA1, HIGH);

digitalWrite (pinA2, LOW);

//5s forward

delay (5000);

//reverse

digitalWrite (pinA1,LOW);

digitalWrite (pinA2,HIGH);

//5s backwards

delay (5000);

//stop

digitalWrite (enableA, LOW);

delay (5000);

//enabling motor B

//Since motor B is mounted reversed, PINs must be exchanged

Serial.println ("Enabling Motor A");

digitalWrite (enableB, HIGH);

//do something

//forward

Serial.println ("Forward");

digitalWrite (pinB1, LOW);

digitalWrite (pinB2, HIGH);

//5s forward

delay (5000);

//reverse

digitalWrite (pinB1,HIGH);

digitalWrite (pinB2,LOW);

//5s backwards

delay (5000);

//stop

digitalWrite (enableB, LOW);

delay (5000);

}

Kaivuri testi 4.ino

Servo servo_1; //initialize a servo object for the connected servo

Servo servo_2; //initialize a servo object for the connected servo

Servo servo_3; //initialize a servo object for the connected servo

int angle1 = 0;

int angle2 = 0;

int angle3 = 0;

int potentio1 = A1; // initialize the A0analog pin for potentiometer

int potentio2 = A0; // initialize the A1analog pin for potentiometer

int potentio3 = A2; // initialize the A1analog pin for potentiometer

int potentio4 = A3; // initialize the A1analog pin for potentiometer

#define SERVO1PIN 7

#define SERVO2PIN 9

#define SERVO3PIN 10

void setup()

{

servo_1.attach(SERVO1PIN); // attach the signal pin of servo to pin9 of arduino

servo_2.attach(SERVO2PIN); // attach the signal pin of servo to pin9 of arduino

servo_3.attach(SERVO3PIN); // attach the signal pin of servo to pin9 of arduino

}

void loop()

{

angle1 = analogRead(potentio1); // reading the potentiometer value between 0 and 1023

angle1 = map(angle1, 0, 1023, 60, 140); // scaling the potentiometer value to angle value for servo between 0 and 180)

servo_1.write(angle1); //command to rotate the servo to the specified angle

delay(5);

angle2 = analogRead(potentio2); // reading the potentiometer value between 0 and 1023

angle2 = map(angle2, 0, 1023, 0, 179); // scaling the potentiometer value to angle value for servo between 0 and 180)

servo_2.write(angle2); //command to rotate the servo to the specified angle

delay(5);

angle3 = analogRead(potentio3); // reading the potentiometer value between 0 and 1023

angle3 = map(angle3, 0, 1023, 30, 160); // scaling the potentiometer value to angle value for servo between 0 and 180)

servo_3.write(angle3); //command to rotate the servo to the specified angle

delay(5);

}

EEZYbotARM

EEZYbotARM mk1

EEZYbotARM mk2